Transporting hazardous chemicals is a dangerous process that carries risk for those in the business of transporting chemicals in bulk.

That is why there are safety measures in place to protect workers in the supply chain from potential risks and hazards.

One of these key safety measures is Safety Data Sheets (SDS), which can sometimes be called a data safety sheet.

Formerly known as, MSDS (Material Safety Data Sheets) the information these documents hold are vital when transporting chemicals and hazardous materials.

In this article we will take a closer look at what SDS’ are and convey their importance.

What are Safety Data Sheets (SDS)?

Safety Data Sheets (SDS) are documents that provide detailed information about the potential hazards and safe handling procedures for chemical products.

These sheets are typically created by the manufacturer, supplier, or importer of a chemical product and are essential for ensuring workplace safety and compliance with regulations.

The information contained in a SDS will allow employers to carry out appropriate risk assessments which are required by the Control of Substances Hazardous to Health Regulations (COSHH). Safety

A SDS alone is not a risk assessment, it serves as a description which aids employers in evaluating the likelihood of workplace hazards by providing information about them. Safety data sheets can sometimes also contain QR codes with more information available online.

They are essential when dealing with hazardous chemicals supplied for workplace use, whether they come in packaging or not.

A SDS is required when a chemical, while not classified as hazardous, contains limited quantities of hazardous substances.

How Can I Get a Safety Data Sheet?

If you’re using a chemical product in a workplace, the supplier or manufacturer of that product is legally obligated to provide you with the SDS upon request.

Contact them directly, and they should be able to provide you with a copy. The supplier or manufacturer’s contact information can typically be found on the product label, packaging, or invoice.

Many organisations and government agencies maintain online databases of SDSs for commonly used chemicals.

EU REACH regulation governed the registration and regulation of chemicals in the European Union, including the UK.

However, after Brexit, the UK established its own regulatory framework for chemicals, UK REACH.

Some manufacturers provide SDS’s on their websites. Look for the manufacturer’s official website and search for a section related to product information or safety data sheets.

If you obtain the chemical through a distributor, they might have access to the SDS for the products they sell. Contact the distributor and request the SDS for the specific product you are using.

What Are the Different Sections of an SDS?

The Safety Data Sheet (SDS) typically contains 16 sections.

These sections provide detailed information about the properties, hazards, safe handling, and emergency response procedures for a chemical product.

We will also look at the impact each section has when it comes to transporting chemicals.

Here are the 16 sections of an SDS:

- Section 1 – Identification: This section provides product identification information, including the product name, manufacturer or supplier details, and contact information.

- Transport impact: Lets the logistics provider know the type of chemical they are dealing with which determines the tanker type.

- Section 2 – Hazard Identification: Here, you’ll find information about the hazards associated with the product, such as its classification, pictograms, signal words, and hazard statements.

- Transport impact: If a chemical is hazardous then it can play a huge role in the restrictions of the tanker and logistics involved.

- Section 3 – Composition/Information on Ingredients: This section lists the chemical ingredients in the product and their concentration or concentration ranges.

- Transport impact: Similar to the previous sections this can determine transportation methods and equipment. Some chemicals will need a specific tanker material.

- Section 4 – First-Aid Measures: It outlines first-aid procedures to follow if someone is exposed to the product, including symptoms and necessary measures.

- Transport impact: Allows drivers and other personnel to be aware of potential hazards and what to do if an accident occurs.

- Section 5 – Fire Fighting Measures: This section provides guidance on how to extinguish fires involving the product, including suitable extinguishing agents and firefighting procedures.

- Transport impact: Drivers and personnel need to be aware of this in case they need to use the appropriate extinguisher for a type of chemical.

- Section 6 – Accidental Release Measures: It describes how to respond to spills, leaks, or releases of the product safely, including containment and cleanup procedures.

- Transport impact: If an accident does occur then staff involved with the transportation process need to know how to respond effectively if a tanker is breached or compromised.

- Section 7 – Handling and Storage: Here, you’ll find information on how to handle, store, and transport the product safely. This includes recommended storage conditions and incompatibilities.

- Transport impact: Gives an understanding on the guidelines on how to store the chemical in a tanker.

- Section 8 – Exposure Controls/Personal Protection: This section details exposure limits, engineering controls, and personal protective equipment (PPE) recommendations for safe handling.

- Transport impact: If contact with a chemical happens then drivers and personnel need to know what to do.

- Section 9 – Physical and Chemical Properties: It provides information about the product’s physical and chemical properties, such as appearance, odour, pH, melting point, and more.

- Transport impact: The odour, melting point and pH are vitally important to know as this will determine whether or not the product is hazardous.

- Section 10 – Stability and Reactivity: This section discusses the product’s stability, reactivity, and conditions to avoid, including incompatible materials and hazardous reactions.

- Transport impact: Stability is the chemical’s shelf life. Reactivity refers to what happens when a chemical comes into contact with another chemical. Both very important points to know for drivers and personnel.

- Section 11 – Toxicological Information: It offers toxicological data, including acute and chronic effects, routes of exposure, and information on the toxicity of the product’s ingredients.

- Transport impact: Staff need to know this as it will affect how they handle, load and unload the material.

- Section 12 – Ecological Information: This section contains information on the product’s environmental impact, including its effects on aquatic and terrestrial ecosystems.

- Transport impact: Gives drivers and other staff the information to know what to do should a chemical be released and how it should be contained.

- Section 13 – Disposal Considerations: It provides guidance on proper disposal methods for the product and any related waste materials, in accordance with local regulations.

- Transport impact: Informs chemical disposal practices for logistics staff.

- Section 14 – Transport Information: If applicable, this section provides information on transportation regulations and requirements for shipping the product.

- Transport impact: This provides logistics providers with insights into the regulations related to the chemical, as well as guidance on the placement of chemical/hazardous material placards on the tank or trailer during transportation.

- Section 15 – Regulatory Information: Here, you’ll find information about relevant regulatory requirements and safety-related regulations.

- Transport impact: This section may expand upon many of the previous sections of the SDS.

- Section 16 – Other Information: This section may include additional information, such as date of preparation, revision, or any other relevant details.

- Transport impact: This allows the driver to see potential changes and revisions made to the SDS. If these aren’t clearly explained they can follow up with the supplier to get a more comprehensive understanding.

Experts in Safely Transporting Chemicals in Bulk

As you can see, SDS’s are extremely vital in the process of transporting chemicals in bulk.

They are only one piece or a larger puzzle, so many more variables are involved in this complex process.

At Sutton Tankers we expertly manage these variables on a daily basis to bring hazardous and non-hazardous chemicals to our customers.

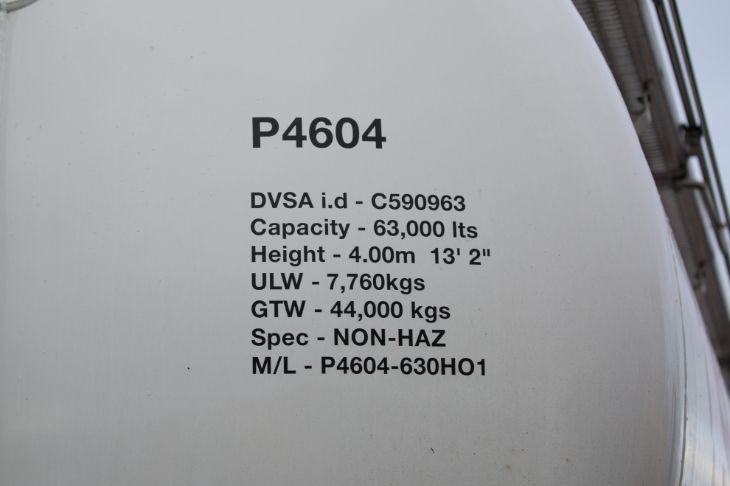

We operate an extensive transport fleet that includes rubber-lined, multi-compartment, and lagged tanks.

These well equipped tanks allow us to transport a wide variety of chemicals safely and efficiently all across the country.

If your business operates in the chemical sector and requires the need for sophisticated bulk chemical logistic solutions, reach out to us today.